|

Product Details:

|

| Type: | Biomass Pellet Machine | Main Power: | 220kw |

|---|---|---|---|

| Ring Die Diamter: | 850 Mm Inner Side | Rollers: | 3 Pcs |

| Machine Gurantee: | 3 Years For Gearbox | Voltage: | 380 Voltage Or Others |

| After-sales Service Provided: | Engineers Available Overseas | Condition: | 100 % New Machine |

| Application: | Fuel Pellets Making | Color: | Blue Or Yellow Or Gray |

| Pellet Size: | 6mm Or 8mm Or 10mm | ||

| Highlight: | 220KW wood pellet machine,Groundnut Shell Wood Pellet Machine,Wood sawdust pellet press machine |

||

220KW Ring Die Wood Sawdust / Rice Husk / Groundnut Shell Pellet Press Making Machine

Introduction:

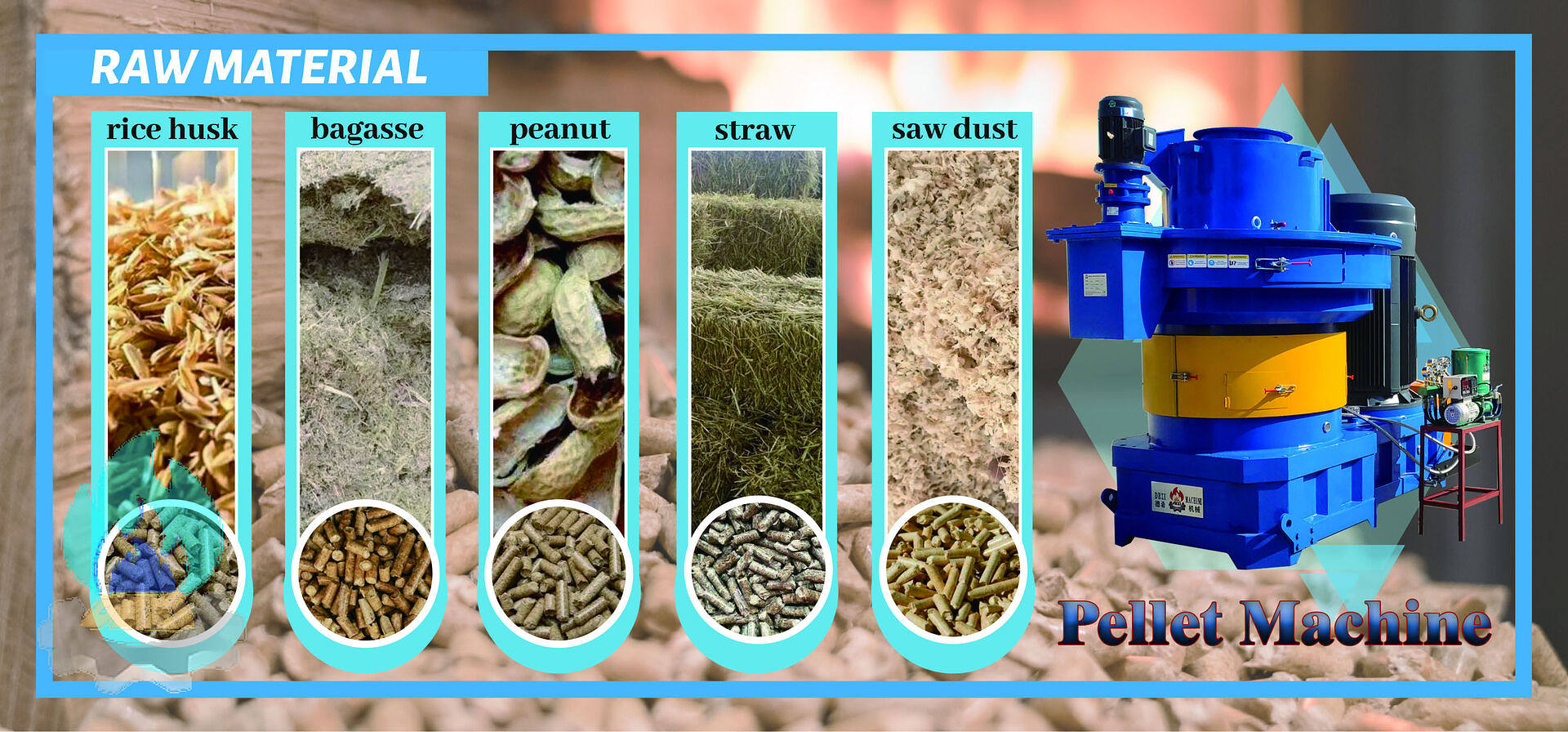

XGJ850P Wood sawdust pellet press machine is mainly using for press different kind of biomass materials to making cylinder shape fuel pellets. The pellets are widely using for industry boiler, different kind of biomass stove, and also home use fireplace or hot air stove.

XGJ850P Biomass pellet making machinegood for press difficult molding materials with low adhesion rate, for example, hard wood sawdust, rice husk, sunflower husk, peanut shell and fruit shell; branch, stem, bark and other wood waste; a variety of crop stalks; rubber, cement, ash and other chemical materials.

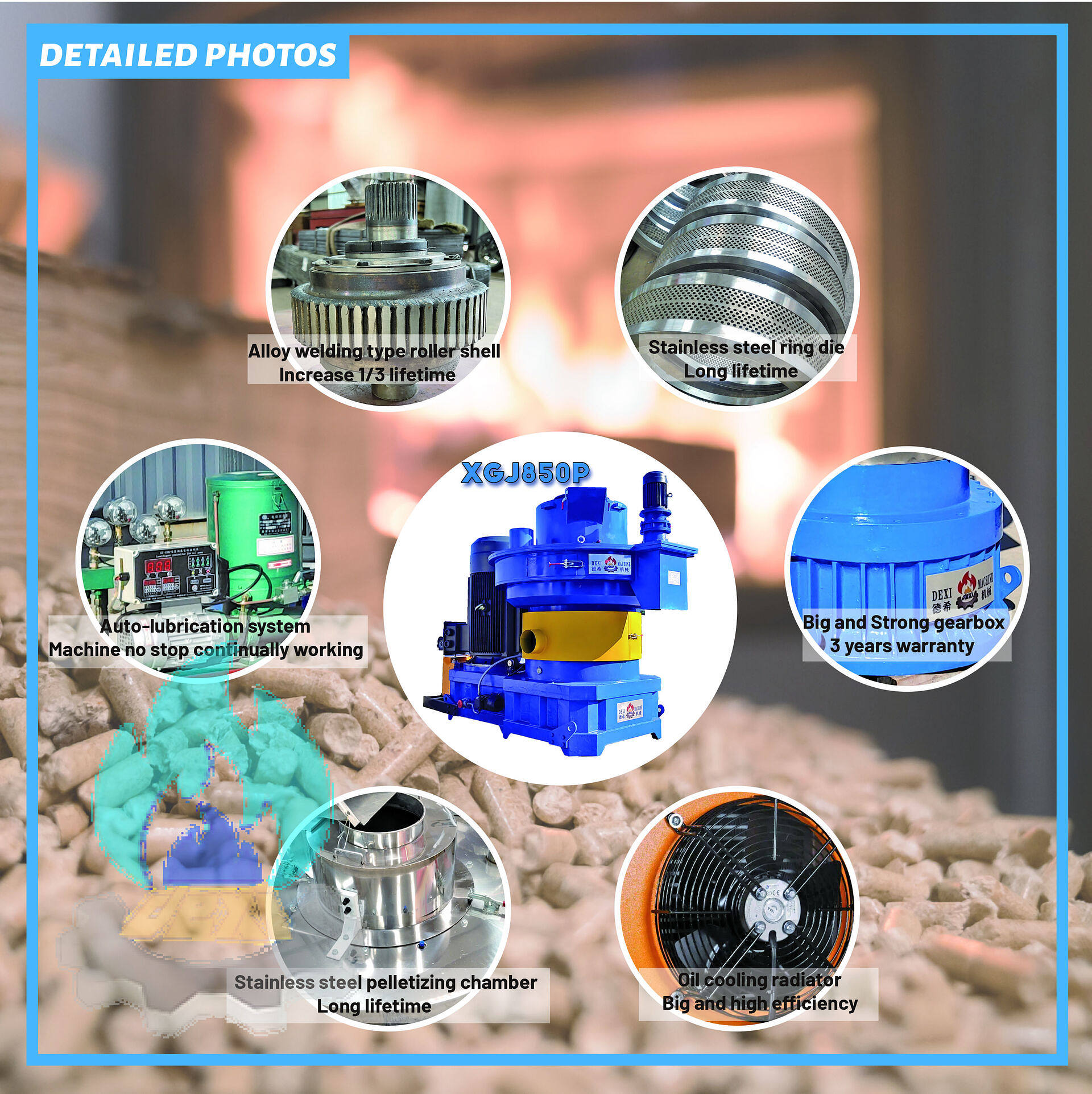

The XGJ850P groundnut shell / rice husk pellet maker machine is update version for XGJ850, same with 3 big roller and big size double layer ring die on the machine, the XGJ850P with bigger and stronger gearbox, make the motor spindle is parallel to the equipment spindle, improve the power transmission efficiency, and lower maintenance ratio.

Mainly Parameter:

| Model | Power (kw) | wood pellets makingCapacity (kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| XGJ460 | 55+1.5+0.55+1.5 | 500-800 | 4200 | 2600x1100x1850 |

| XGJ460P | 55+1.5+0.55+1.5 | 500-800 | 3200 | 2300x1100x1500 |

| XGJ560 | 90+1.5+0.75+0.55+2.2 | 1000-1500 | 6100 | 2600x1300x2300 |

| XGJ560P | 132+1.5+0.75+0.55+2.2 | 1500-2000 | 5400 | 2600x1250x1600 |

| XGJ700P | 160+1.5+0.75+0.55+2.2 | 2000-2500 | 14500 | 3300x1400x3100 |

| XGJ850 | 220+3+0.75+0.55+3 | 2000-3000 | 9600 | 2600x1600x1950 |

| XGJ850P | 220+3+0.75+0.55+3 | 2500-3500 | 13500 | 2650×1850×2100 |

| XGJ850P | 250+3+0.75+0.55+3 | 3000-4500 | 15000 | 2750×1850×2100 |

Photos of Machine:

OUR SERVIC

Pre-sale service

1. Our professional and experienced team helps every client to find his most suitable biomass wood pellet machine and chose the correct chipper, crusher, dryer and other machines for a complete biofuel pellet production plant line.

2. Any kind of legal logo printing or design are available.

3. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

After you choose:

1. We will arrange production immediately based on customer's demand.

2. Empty loading running test once machine finished production.

3. Every equipment will be checked carefully before packing, take photos and video to you for confirmation.

4. Help you arrange shipment booking, machine delivery and help you for your importing documents.

After-sale service

1. 24hours on-line serivce, guide you doing installation and starting using for the purchased machines.

2. Video communication guide your local worker doing installation and commissioning, and normal maintenance.

2. We also can send engineers to customer's factory doing the guide installation for biomass pellet machine line and other big machines.

FAQ

Q. What is your payment term?

A: T/T 30% down payment, balance to be paid before shipment.

Q: What is your main market?

A: Eastern Europe, Southeast Asia, Africa, Oceania, Eastern Asia

Q: What is your delivery time?

A: Producing time depends on which machines you ordered. Roughly all machines we have instock, some new produce produts takes 10 - 30 days.

Q: What documents you can offer?

A: We can offer invoice, packing list, contract, instructions, customs declaration, certificate of origin, CE. If client need other documents, specifications, please confirm with service staff.

Q: If equipments have some quality problem, how would you deal with?

A: We will responsible for all the quality problems. Change all the parts for free.

Contact Person: Mr. Jack

Tel: +86-18615606726